Descubriendo las propiedades versátiles de la película de PVC blando para aplicaciones industriales multifacéticas

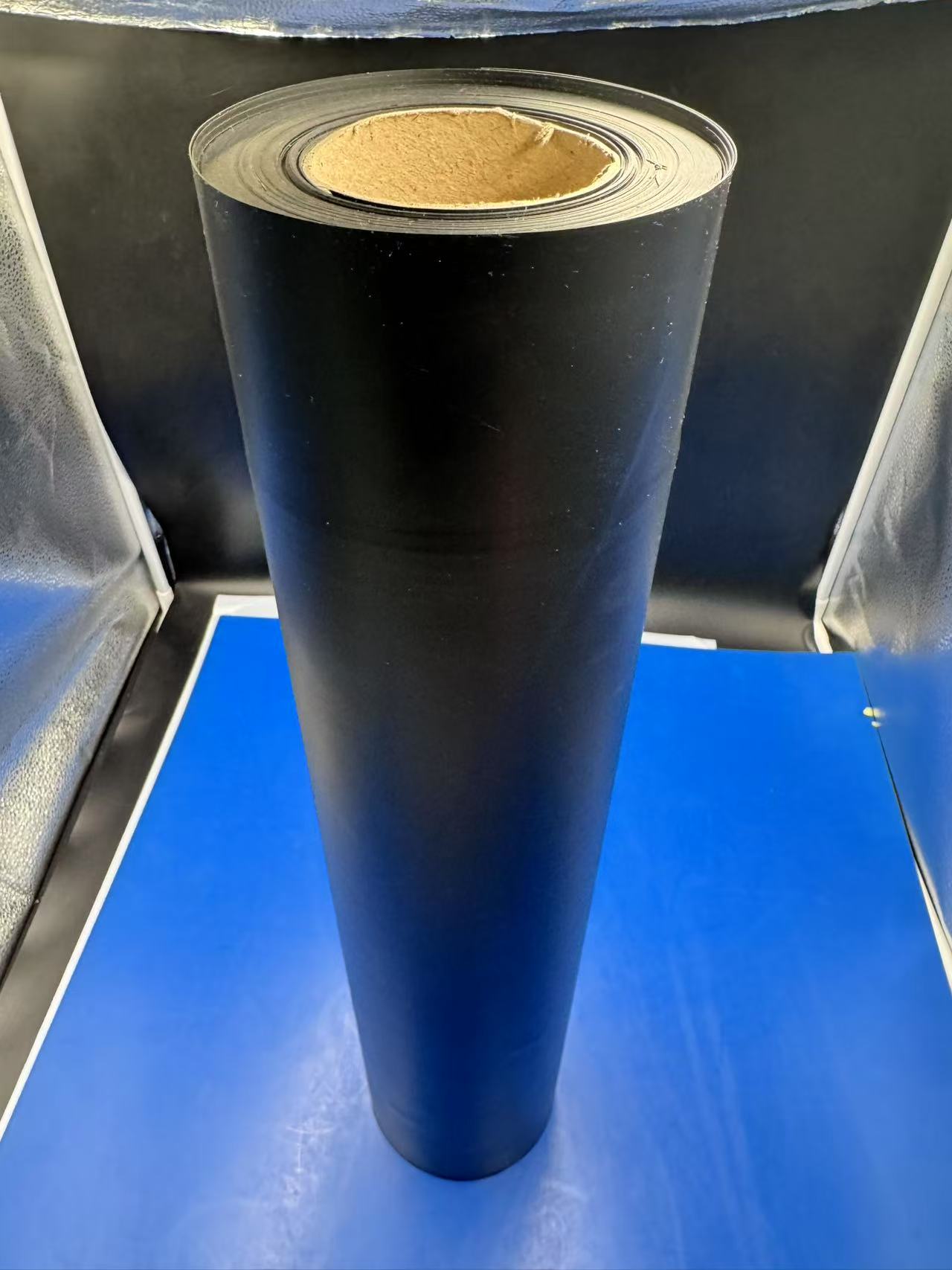

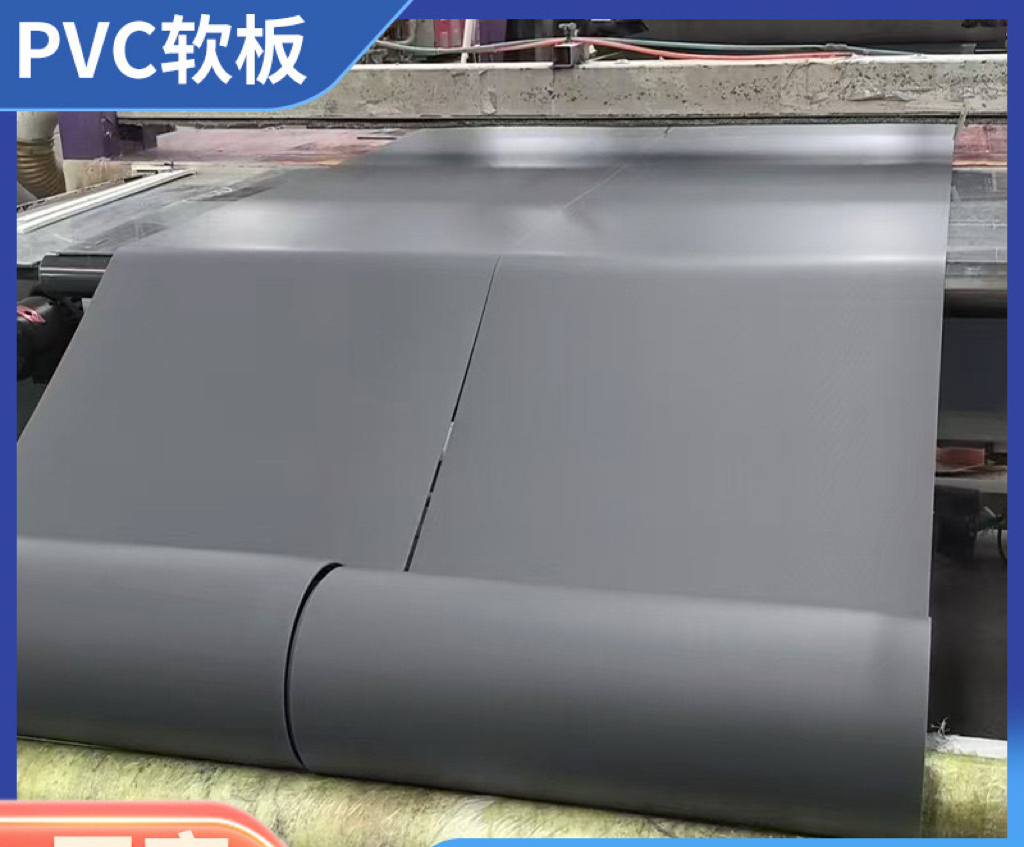

Nombre Rollo de película blanda de PVC

Tamaño Tk: 0,01-3 mm, h100-1200 mm

Material PET/PP/Personalizado

Color/impresión Transparente/personalizado

Cajas de embalaje/personalizadas

Se aceptan OEM/ODM

Cantidad mínima de pedido 1000 kg

Uso Película de PVC blando, resistente a la corrosión, ignífuga, impermeabilizante, antiestática.

Característica Alta durabilidad, ecológico, resistencia a la compresión.

Ventaja Precio competitivo, calidad constante, servicio en línea las 24 horas.

- TOPLEADER

- PORCELANA

- 15 DÍAS LABORABLES

- 5000 toneladas por metro

- información

- vídeo

- descargar

Desafíos e innovaciones futuras

In the realm of industrial materials, soft PVC film (Polyvinyl Chloride film) stands out as a versatile, durable, and cost-effective solution. Renowned for its adaptability, this flexible plastic film is engineered to meet a wide range of challenges, from corrosion and fire to water, oil, and static electricity. Its ability to resist aging, wear, acids,  and alkalis further cements its role across industries like construction, electronics, packaging, and manufacturing. This article explores the defining characteristics of soft PVC film and its practical applications in combating corrosion, fire, water, oil, static, aging, wear, and chemical degradation, offering a detailed, evidence-based narrative that highlights its real-world impact.

and alkalis further cements its role across industries like construction, electronics, packaging, and manufacturing. This article explores the defining characteristics of soft PVC film and its practical applications in combating corrosion, fire, water, oil, static, aging, wear, and chemical degradation, offering a detailed, evidence-based narrative that highlights its real-world impact.

Characteristics of Soft PVC Film

Soft PVC film is produced by plasticizing polyvinyl chloride resin with additives like plasticizers, stabilizers, and flame retardants, resulting in a flexible, transparent, or colored film with tailored properties. Its key characteristics include:

Flexibility and Conformability

Unlike rigid plastics, soft PVC film is pliable, allowing it to conform to irregular shapes and surfaces. This flexibility makes it ideal for wrapping, coating, or lining applications, ensuring seamless coverage even on complex geometries.

Customizable Formulations

Manufacturers can adjust the composition of soft PVC film to enhance specific properties, such as fire resistance or chemical stability. Additives like UV stabilizers, antistatic agents, or flame retardants enable the film to meet diverse industry standards.

Durability and Cost-Effectiveness

Soft PVC film combines robustness with affordability. Its resistance to environmental stressors reduces maintenance costs, while its low production cost makes it accessible for large-scale applications.

Transparency and Aesthetic Versatility

Available in clear, translucent, or opaque forms, soft PVC film offers aesthetic flexibility. Clear versions provide visibility, while colored or patterned options enhance branding or safety signaling.

Ease of Processing

The film can be cut, welded, printed, or laminated with ease, enabling rapid customization. This processability supports high-speed manufacturing, reducing downtime and costs.

Applications of Soft PVC Film in Specialized Functions

Soft PVC film excels in addressing eight critical challenges: corrosion, fire, water, oil, static electricity, aging, wear, and acid/alkali exposure. Below, we explore each application in detail, illustrating how the film’s properties translate into practical solutions.

1. Corrosion Resistance

Corrosion, the deterioration of metals due to chemical reactions, poses a significant threat to infrastructure and equipment. Soft PVC film serves as an effective barrier, preventing moisture, salts, and corrosive gases from reaching metal surfaces. For example, in marine environments, steel pipes coated with soft PVC film resist rust caused by saltwater exposure. The film’s flexibility allows it to wrap tightly around joints and fittings, ensuring no gaps for corrosive agents to penetrate. In chemical plants, soft PVC film linings protect storage tanks from acidic vapors, extending their lifespan and reducing maintenance costs. Its chemical inertness ensures long-term protection without degrading under harsh conditions.

2. Fireproofing

Fire safety is paramount in industries like construction and transportation. Soft PVC film can be formulated with flame-retardant additives, achieving classifications like UL94 V-0, which indicates self-extinguishing properties. In buildings, soft PVC film is used as a fire-resistant curtain or cladding, slowing the spread of flames and reducing smoke production. For instance, in a warehouse storing flammable goods, soft PVC film partitions create firebreaks, buying critical time for evacuation and firefighting. Its low heat conductivity also prevents it from fueling fires, unlike untreated plastics. This fireproofing capability makes soft PVC film a trusted choice for safety-conscious applications.

3. Waterproofing

Waterproofing is essential for protecting structures, electronics, and goods from moisture damage. Soft PVC film boasts a near-zero water vapor transmission rate, making it an excellent barrier against water ingress. In construction, it’s used as a geomembrane to line ponds, canals, and roofs, preventing leaks. For example, a rooftop covered with soft PVC film remains impervious to heavy rainfall, safeguarding the building’s interior. In packaging, soft PVC film wraps electronic components, keeping them dry during transport through humid climates. Its flexibility ensures a tight seal, even around irregular shapes, providing reliable waterproofing in diverse scenarios.

4. Oil Resistance

Oil and grease can degrade many materials, but soft PVC film resists these substances effectively. Its non-polar surface repels oils, preventing absorption or swelling. In automotive workshops, soft PVC film covers floors, protecting them from oil spills during maintenance. In food processing, conveyor belts coated with soft PVC film withstand exposure to cooking oils without deteriorating, ensuring hygiene and durability. For instance, a meat processing plant might use soft PVC film to line equipment surfaces, allowing easy cleanup of greasy residues while maintaining structural integrity.

5. Anti-Static Properties

Static electricity can damage sensitive electronics or ignite flammable gases. Soft PVC film can be treated with antistatic agents to dissipate static charges, ensuring safety and reliability. In cleanrooms, soft PVC film curtains prevent static buildup, protecting microchips during assembly. For example, a semiconductor manufacturer might use soft PVC film to wrap circuit boards, neutralizing static risks during storage. In fuel depots, soft PVC film linings on equipment reduce the chance of sparks, enhancing safety. This anti-static feature is critical in high-precision and hazardous environments.

6. Anti-Aging (UV and Oxidation Resistance)

Exposure to sunlight and oxygen accelerates material degradation, but soft PVC film counters this through UV stabilizers and antioxidants. These additives prevent yellowing, brittleness, and cracking, ensuring longevity. In outdoor applications, such as greenhouse covers, soft PVC film withstands years of UV radiation while maintaining clarity for optimal light transmission. For instance, a farmer using soft PVC film to cover crops benefits from its durability, avoiding frequent replacements. In signage, soft PVC film protects printed graphics from fading, preserving vibrant colors despite prolonged sun exposure.

7. Wear Resistance

High-traffic environments demand materials that endure abrasion and mechanical stress. Soft PVC film is engineered for wear resistance, maintaining its integrity under friction. In factories, soft PVC film is used as protective matting, shielding floors from heavy machinery and foot traffic. For example, a logistics hub might install soft PVC film flooring to withstand constant forklift movement, reducing wear and tear. In conveyor systems, the film’s smooth, tough surface resists scratches from sharp objects, ensuring uninterrupted operation. Its ability to absorb minor impacts further enhances its suitability for demanding settings.

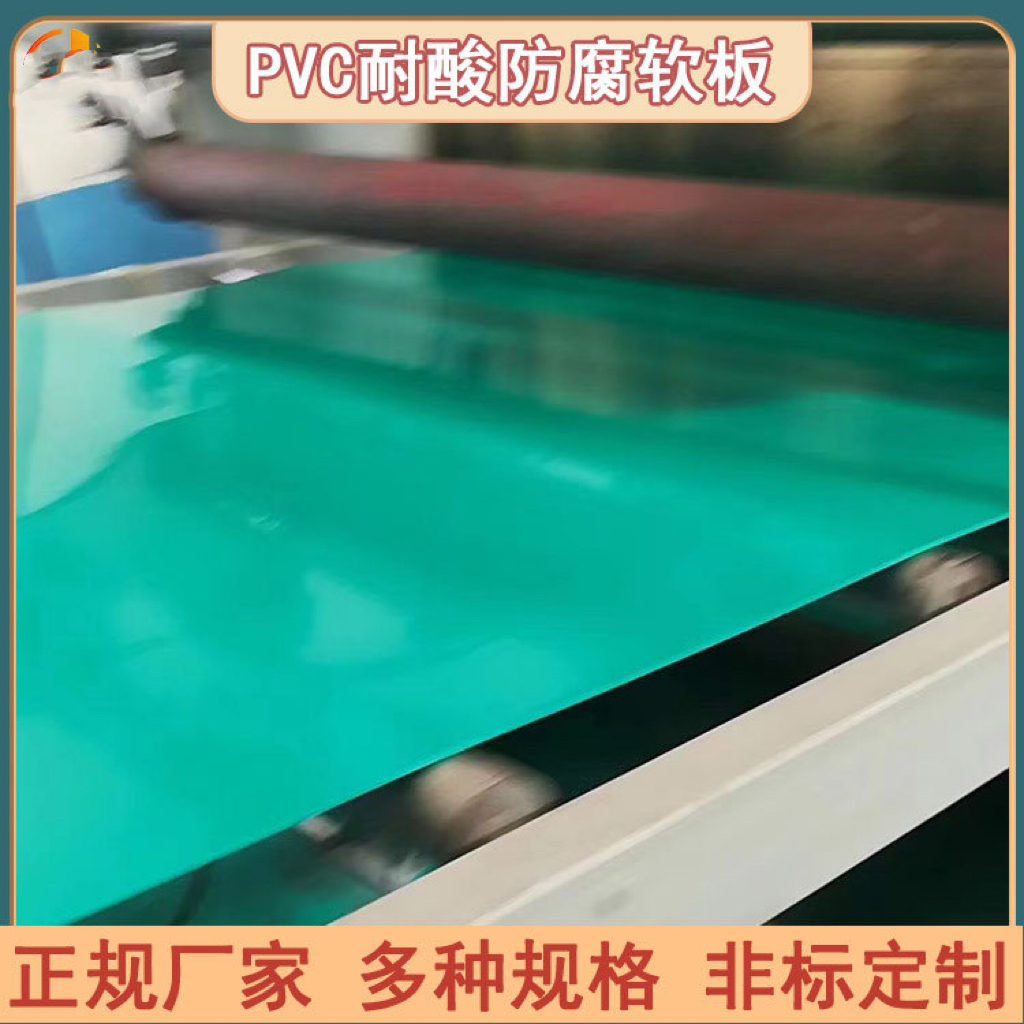

8. Acid and Alkali Resistance

Chemical resistance is vital in industries handling aggressive substances. Soft PVC film is inherently resistant to acids, alkalis, and salts, making it ideal for harsh environments. In laboratories, soft PVC film lines fume hoods, protecting surfaces from spills of sulfuric acid or sodium hydroxide. In wastewater treatment plants, pipes coated with soft PVC film resist corrosion from alkaline effluents, ensuring reliable performance. For example, a chemical manufacturer might use soft PVC film to wrap storage drums, preventing damage from acidic leaks. This resistance ensures safety and durability in chemically intensive applications.

Real-World Impact and Examples

The versatility of soft PVC film is evident in its widespread adoption. In construction, a skyscraper’s roofing system might incorporate soft PVC film for waterproofing, ensuring decades of leak-free performance. In electronics, a smartphone assembly line uses soft PVC film curtains to maintain a static-free environment, boosting production yields. In agriculture, soft PVC film greenhouse covers protect crops from rain while resisting UV degradation, supporting sustainable farming.

Consider a chemical processing plant where soft PVC film lines storage tanks. The film’s acid resistance prevents corrosion, while its flexibility accommodates thermal expansion, avoiding cracks. Similarly, in a hospital, soft PVC film flooring resists wear from constant foot traffic and chemical spills from disinfectants, maintaining a hygienic environment. These examples underscore how soft PVC film delivers tangible benefits across sectors.

Challenges and Future Innovations

Dentro de 15-20 días después del pago recibido...more