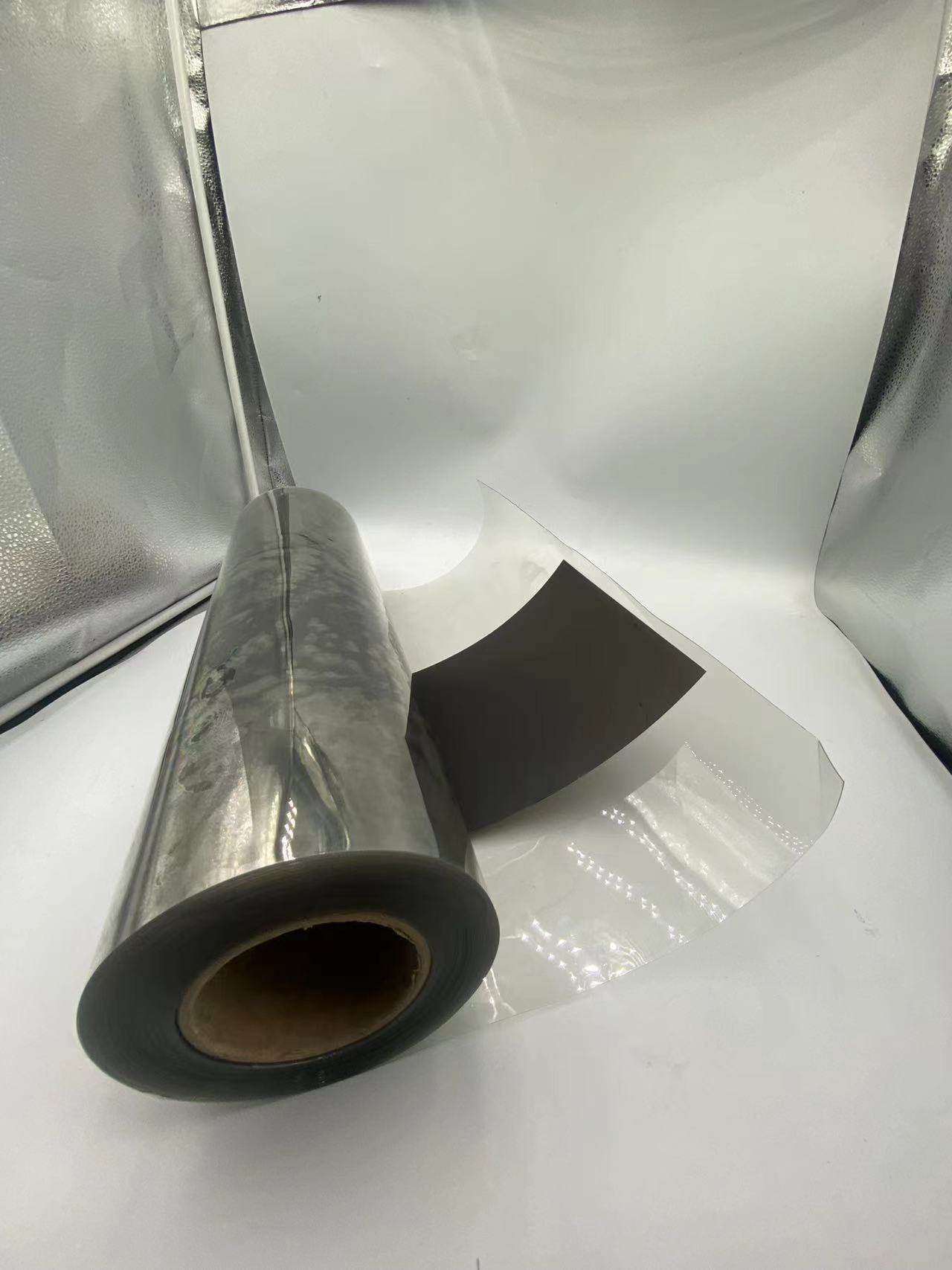

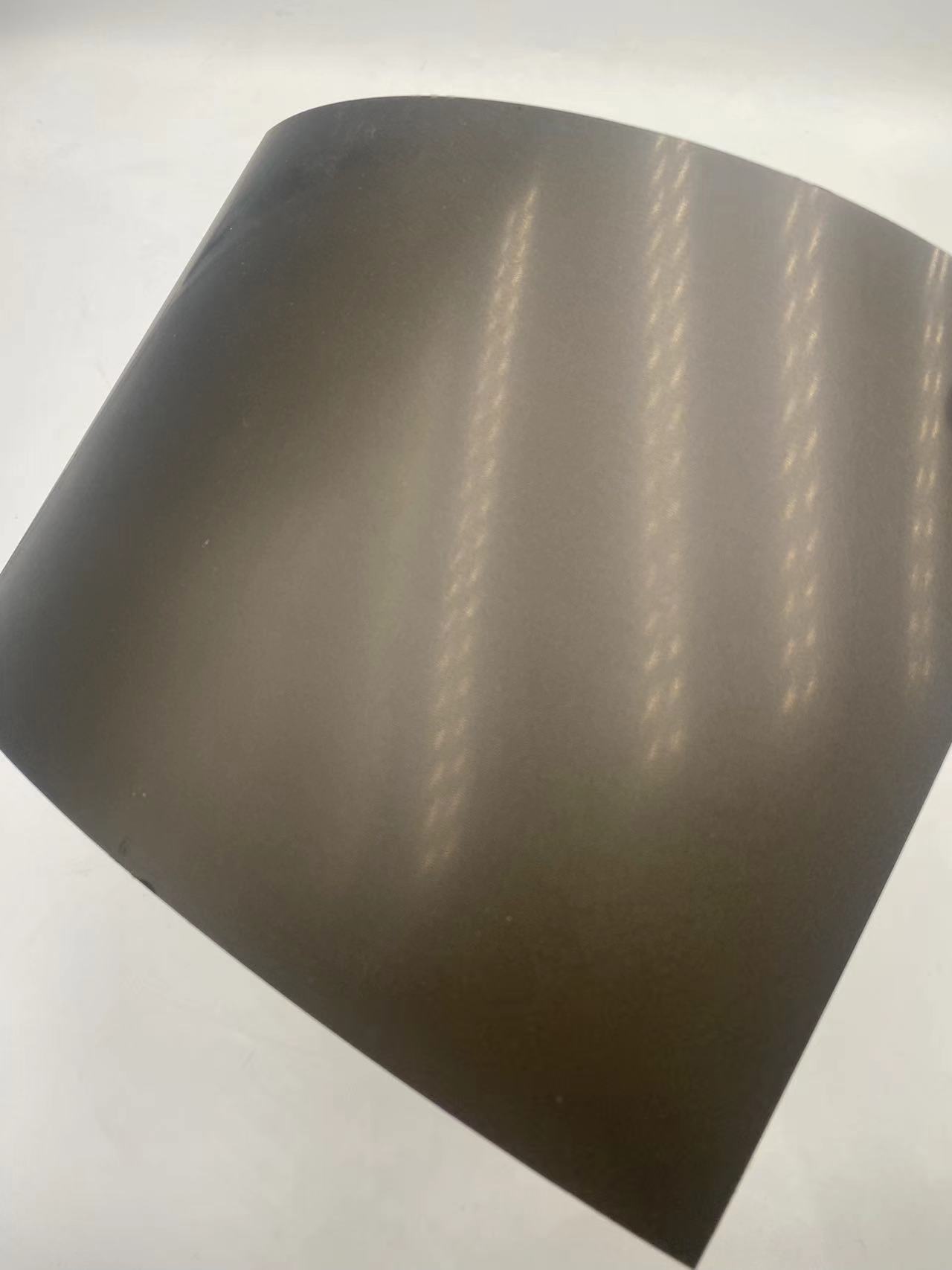

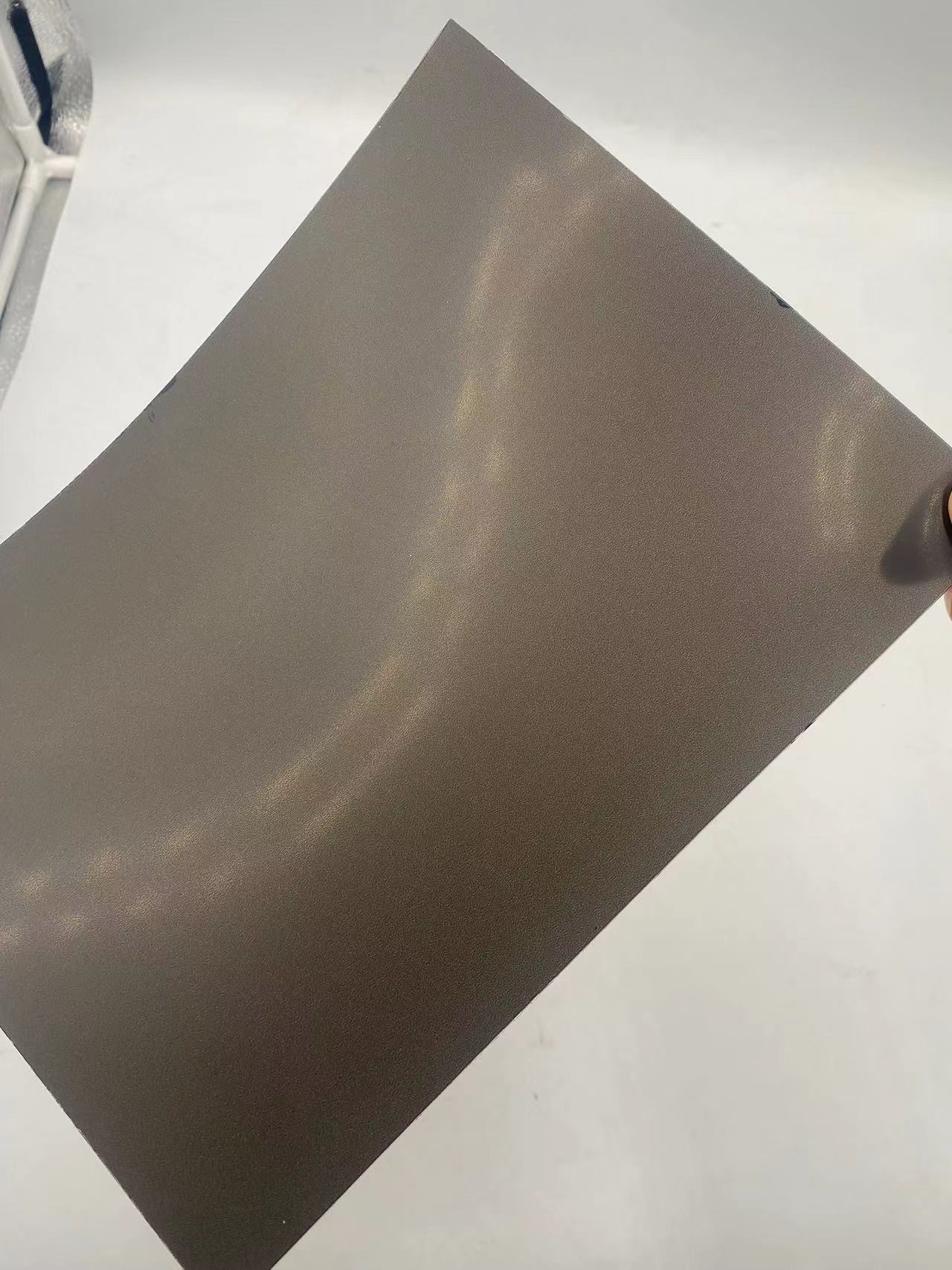

96 Las diversas aplicaciones de la película PET negra en los sectores electrónico y eléctrico

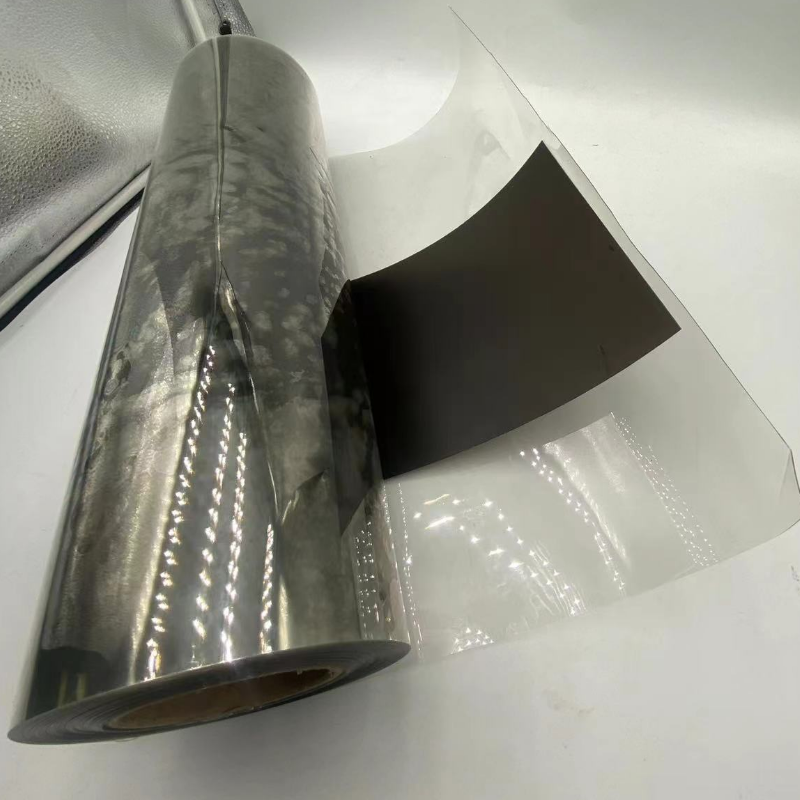

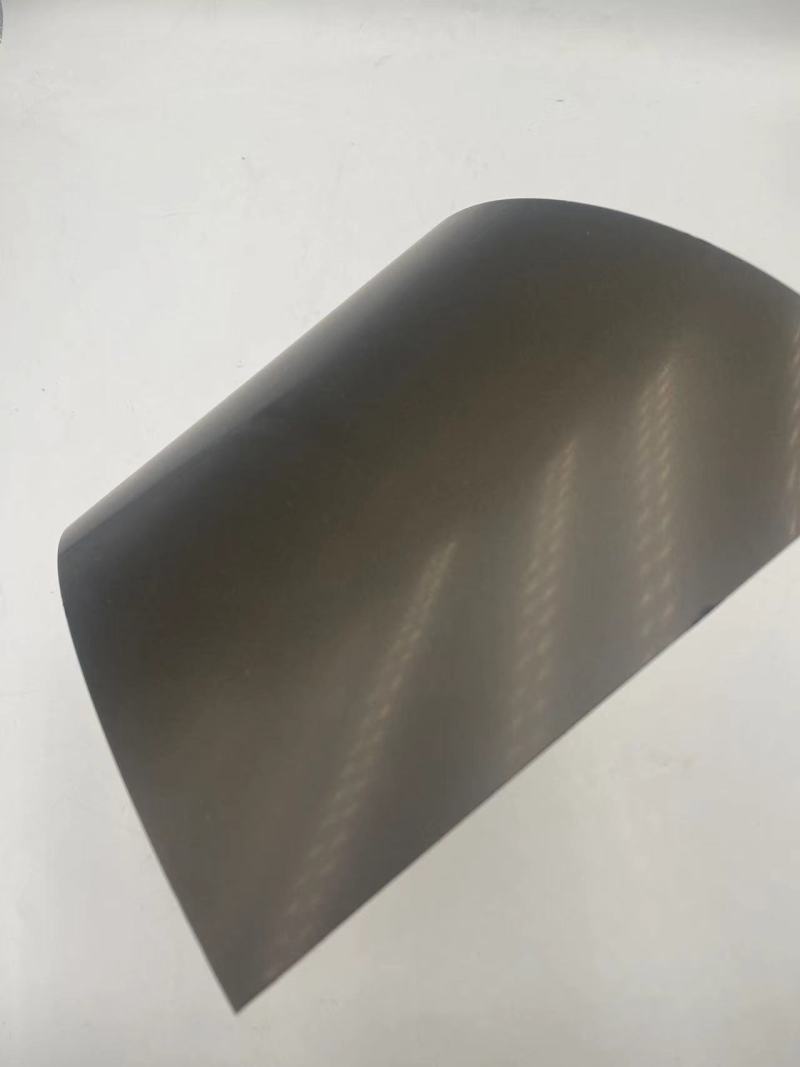

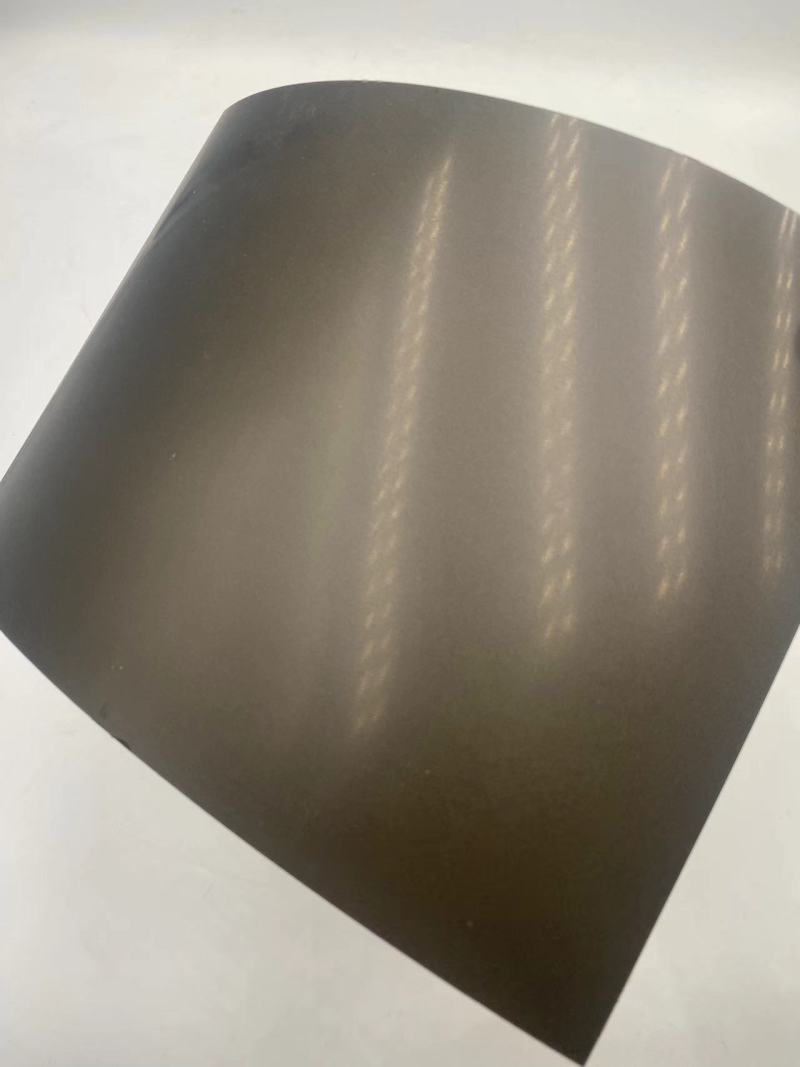

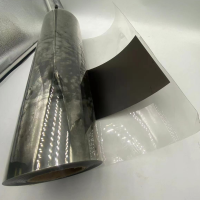

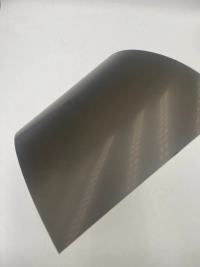

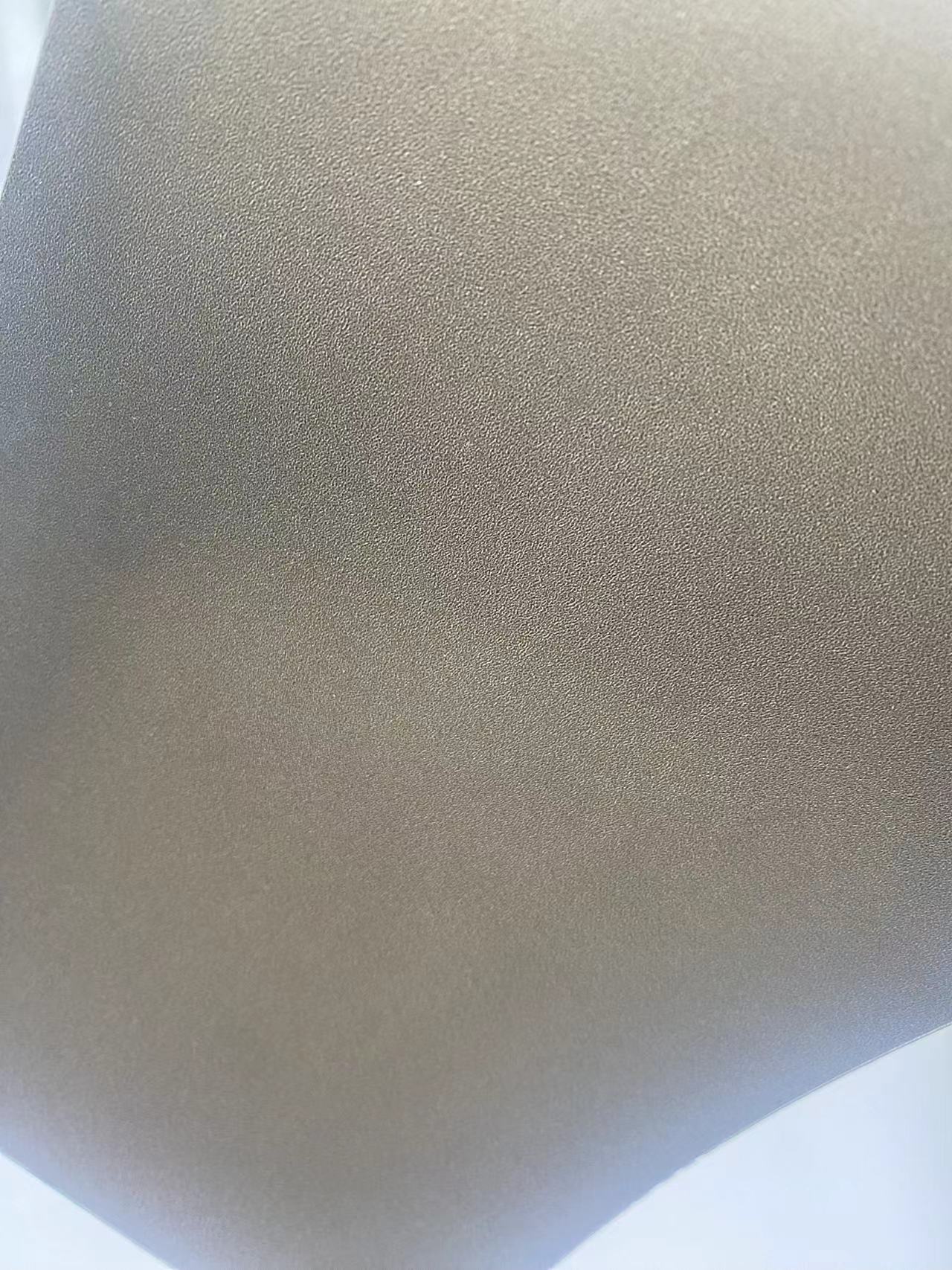

Material: PET Hoja imprimible

Espesor 0,012 mm/personalización

Tamaño: 100 mm/Personalización

GRADO: Película de calidad alimentaria

Color: negro/personalización

Ubicación: China

Uso: para sectores electrónicos y eléctricos.

- TOPLEADER

- porcelana

- 15 DÍAS LABORABLES

- 5000 toneladas por metro

- información

- vídeo

- descargar

6.2 Sensores de presión y deformación

En los sensores de presión y tensión, la película PET negra se puede utilizar como sustrato flexible o como parte del elemento sensor. La flexibilidad de la película le permite deformarse bajo presión o tensión, y esta deformación se puede medir y convertir en una señal eléctrica. Por ejemplo, en un teclado táctil o en una resistencia de detección de fuerza, la película PET negra proporciona una plataforma flexible y duradera para el mecanismo de detección. También se puede integrar con otros materiales, como tintas conductoras o polímeros piezorresistivos, para mejorar la sensibilidad y el rendimiento del sensor.

7. Conclusión

La película PET negra se ha consolidado como un material vital en las industrias electrónica y eléctrica. Sus aplicaciones en tecnologías de visualización, placas de circuitos impresos, embalajes electrónicos, aislamiento eléctrico y sensores electrónicos han contribuido significativamente al avance y la fiabilidad de los dispositivos electrónicos y eléctricos modernos. La combinación única de propiedades como el color negro, la resistencia mecánica, la flexibilidad y la resistencia química la convierten en la opción preferida de muchos fabricantes.

A medida que la tecnología siga evolucionando, es probable que aumente la demanda de películas PET negras. Los esfuerzos futuros de investigación y desarrollo pueden centrarse en mejorar su rendimiento en áreas como la conductividad para el blindaje contra interferencias electromagnéticas, una mayor flexibilidad para dispositivos electrónicos portátiles y flexibles y mejores propiedades ópticas para aplicaciones avanzadas de visualización y sensores. La versatilidad y adaptabilidad de las películas PET negras garantizan que seguirán siendo un actor clave en los sectores electrónico y eléctrico, lo que permitirá la innovación y el desarrollo de productos nuevos y mejorados.

Cabe señalar que este artículo solo toca la superficie de las aplicaciones extensas y en constante expansión de la película PET negra, y que el campo está repleto de oportunidades para una mayor exploración y descubrimiento.

In liquid crystal displays (LCDs), black PET film is widely used in backlighting units. It serves as a reflector and a light guide enhancer. The black color of the film helps to absorb stray light and prevent internal reflections, thereby increasing the contrast and clarity of the displayed images. For example, in a laptop computer screen, the black PET film in the backlighting system ensures that the light from the LEDs or CCFLs is efficiently directed towards the liquid crystal layer, providing a bright and vivid visual experience. It also helps to maintain a consistent color temperature across the display, which is crucial for accurate color reproduction in applications such as photo and video editing.

2.2 Frame and Masking in Displays

Black PET film is used for framing and masking purposes in various display technologies. It can be cut and shaped to form the bezels around the active display area. The black color gives a sleek and professional appearance, enhancing the overall aesthetics of the device. In OLED displays, for instance, the black PET film is used to mask the non-emitting areas, creating a seamless transition between the active and inactive regions of the screen. This not only improves the visual appeal but also helps to protect the delicate organic layers from external contaminants and physical damage.

2.3 Touch Screen Layers

In touch screen panels, black PET film can be incorporated as a part of the sensor stack. It provides a stable and durable substrate for the deposition of conductive layers such as indium tin oxide (ITO) or other transparent conductive materials. The film's flexibility allows it to be used in both rigid and flexible touch screen designs. For example, in a smartphone with a curved-edge display, the black PET film underneath the touch sensor layer enables the device to maintain its structural integrity while providing accurate touch response. It also helps to reduce the visibility of the internal circuitry and sensor components, giving a more immersive viewing experience.

3. Applications in Printed Circuit Boards (PCBs)

3.1 Solder Mask and Insulation

Black PET film is used as a solder mask in printed circuit boards. It protects the copper traces and other components on the PCB from solder bridges and short circuits during the soldering process. The black color also provides a good contrast, making it easier for technicians to inspect and identify the circuitry. Additionally, the film acts as an insulator, preventing electrical leakage between adjacent traces. In high-density PCBs used in advanced electronics like motherboards for gaming PCs or server boards, the black PET film solder mask ensures the reliable operation of the complex circuitry by providing both protection and insulation.

3.2 Flexible PCB Substrates

With the increasing demand for flexible electronics, black PET film has emerged as a popular choice for flexible printed circuit board (FPCB) substrates. It offers a good balance of flexibility and mechanical strength, allowing the FPCB to be bent and folded without breaking. The film's surface can be treated to enhance its adhesion with conductive inks or metal foils, enabling the fabrication of high-quality conductive traces. For example, in wearable devices such as fitness trackers or smartwatches, the flexible PCB made with black PET film substrate can conform to the shape of the human body, providing a comfortable and reliable electrical connection between different components like sensors, microprocessors, and batteries.

3.3 EMI Shielding Films in PCBs

Electromagnetic interference (EMI) is a major concern in modern electronic devices. Black PET film can be coated with conductive materials to create EMI shielding films. These films are applied to PCBs to prevent the emission of electromagnetic radiation from the circuitry, which can cause interference with other nearby electronic components. At the same time, they also protect the PCB from external EMI sources. In a smartphone PCB, for instance, the EMI shielding film made from black PET film helps to ensure the proper functioning of the radio frequency (RF) modules, Wi-Fi chips, and other sensitive components by blocking out unwanted electromagnetic signals.

4. Applications in Electronic Packaging

4.1 Anti-Static and ESD Protection

Black PET film is used in electronic packaging to provide anti-static and electrostatic discharge (ESD) protection. It can be incorporated into packaging materials such as bags, trays, and wraps. The film dissipates static charges, preventing them from building up and causing damage to sensitive electronic components. For example, when microchips or other semiconductor devices are transported or stored, the anti-static black PET film packaging ensures that they are protected from ESD events. This is crucial in semiconductor manufacturing and electronics assembly plants, where even a small electrostatic discharge can render expensive components useless.

4.2 Moisture and Dust Barrier

In addition to its anti-static properties, black PET film serves as an excellent moisture and dust barrier in electronic packaging. It helps to protect the electronic devices from environmental factors that can affect their performance and reliability. The film's low permeability to moisture and dust keeps the internal components dry and clean. For instance, in the packaging of cameras, smartphones, or other portable electronics, the black PET film helps to maintain the integrity of the device by preventing moisture ingress and dust accumulation, which could lead to corrosion, short circuits, or other malfunctions.

4.3 Tamper-Evident Packaging

Black PET film can be designed to provide tamper-evident features in electronic packaging. It can be made with a special adhesive or a tear-resistant structure. Once the package is opened, it shows visible signs of tampering, giving consumers and manufacturers confidence in the integrity of the product. For example, in the packaging of high-value electronic components or software CDs, the tamper-evident black PET film packaging ensures that the contents have not been accessed or altered before reaching the end-user.

5. Applications in Electrical Insulation and Protection

5.1 Insulation in Transformers and Motors

In the electrical power industry, black PET film is used for insulation in transformers and motors. It provides a thin and flexible layer of insulation between the conductive windings and other components. The film's high dielectric strength and thermal stability make it suitable for withstanding the high voltages and temperatures present in these electrical devices. For example, in a power transformer, the black PET film insulation helps to prevent electrical breakdown and short circuits, ensuring the efficient and safe transfer of electrical energy. It also helps to reduce the size and weight of the transformer by allowing for a more compact winding design.

5.2 Cable Wraps and Harnesses

Black PET film is used as a cable wrap and in cable harnesses. It protects the cables from external abrasion, chemical exposure, and UV radiation. The film's flexibility allows it to be easily wrapped around cables of different diameters. In automotive wiring harnesses, for example, the black PET film provides a durable and protective covering for the electrical cables, preventing them from being damaged by the harsh environment under the hood or inside the vehicle. It also helps to organize and bundle the cables, making the wiring system more manageable and reliable.

6. Applications in Electronic Sensors

6.1 Optical Sensors and Filters

Black PET film can be used in optical sensors and filters. It can be coated with special materials to create filters that block specific wavelengths of light. For example, in infrared (IR) sensors, the black PET film filter can be designed to allow only IR light to pass through, while blocking visible light and other unwanted wavelengths. This helps to improve the sensitivity and accuracy of the sensor. In a security camera with night vision capabilities, the black PET film optical filter enhances the detection of IR radiation, enabling the camera to capture clear images in low-light or dark conditions.

6.2 Pressure and Strain Sensors

In pressure and strain sensors, black PET film can be used as a flexible substrate or as a part of the sensing element. The film's flexibility allows it to deform under pressure or strain, and this deformation can be measured and converted into an electrical signal. For example, in a touch-sensitive keypad or a force-sensing resistor, the black PET film provides a flexible and durable platform for the sensing mechanism. It can also be integrated with other materials such as conductive inks or piezoresistive polymers to enhance the sensitivity and performance of the sensor.

7. Conclusion

Black PET film has established itself as a vital material in the electronic and electrical industries. Its applications in display technologies, printed circuit boards, electronic packaging, electrical insulation, and electronic sensors have significantly contributed to the advancement and reliability of modern electronic and electrical devices. The unique combination of properties such as black color, mechanical strength, flexibility, and chemical resistance makes it a preferred choice for many manufacturers.

As technology continues to evolve, the demand for black PET film is likely to increase. Future research and development efforts may focus on improving its performance in areas such as conductivity for EMI shielding, enhanced flexibility for wearable and flexible electronics, and better optical properties for advanced display and sensor applications. The versatility and adaptability of black PET film ensure that it will remain a key player in the electronic and electrical sectors, enabling the innovation and development of new and improved products.

It should be noted that this article only scratches the surface of the extensive and ever-expanding applications of black PET film, and the field is ripe with opportunities for further exploration and discovery.

Dentro de 15-20 días después del pago recibido...more